Exploring AMR

Together

Cost Savings and Efficiency

With autonomous navigation, automated material handling and transportation, the AMR replaces manual operations, integrates precisely into various production processes and adapts to different working environments.

How long does it take to deploy AMRs? Is it complicated?

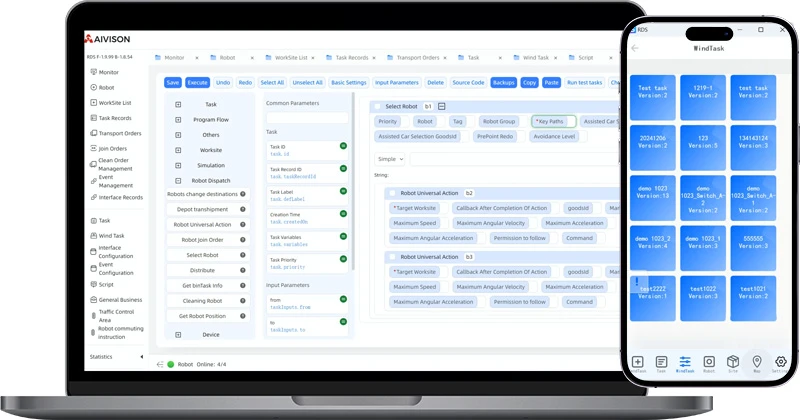

After resolving how to select the appropriate type and addressing any concerns about AMR functionality, AMRs can be deployed in factories or warehouses. Through our unified dispatch system RDS and one-stop implementation tool Roboshop, the deployment of AMRs can be quickly achieved.

RDS

Synergistic Resource Dispatch of Robotics and Automation Equipment

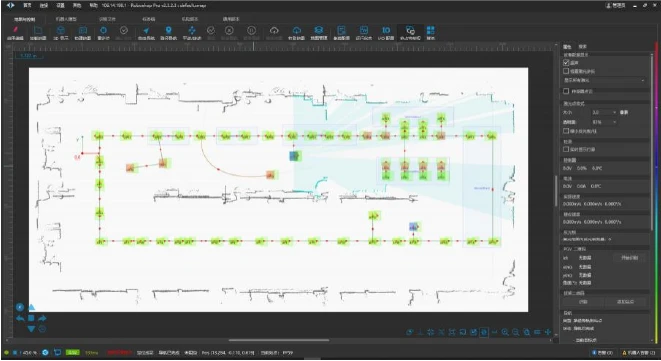

What You See is What You Get

Instruction

Get Rid of Empty Load Anxiety

Dynamic Global Collaborative Planning

- Based on an integrated evaluation function, RDS considers the global optimal task;

- Pre-order mode is available for the “warehouse – production line” round trip transportation;

- For multi – storage robots, RDS provides a join – order mode.

High Adaptation

Consider Hitchhiking and Pre-order Task Dispatching

Unlike traditional grid point matrix maps, RDS enables multi – robot path search and traffic control through dynamic global collaborative planning in scenarios with any structured routes and human interference, enabling robots to effectively avoid congestion and prevent and release deadlocks in a timely manner.

What You See is What You Operate

Panoramic Business and Scheduling Simulation

- We are able to simulate hundreds of robots simultaneously;

- The simulation results can be directly applied to real business.

Keep Track of the Whole Progress

Visualisation of the Task Process

In the RDS task management interface, users can monitor the status and progress of tasks in real time, as well as details of actions being performed by the relevant devices, resources being requested, or faults and exceptions being triggered. The users can keep track of the whole progress as well as quickly pinpoint problems for specific task.

Intuitive and Simple UI Interaction

Mobile Terminal APP Configuration Customisation

By writing configuration files and scripts, users can create a simple, fool – proof mobile app tailored to their business.

Easy to Handle

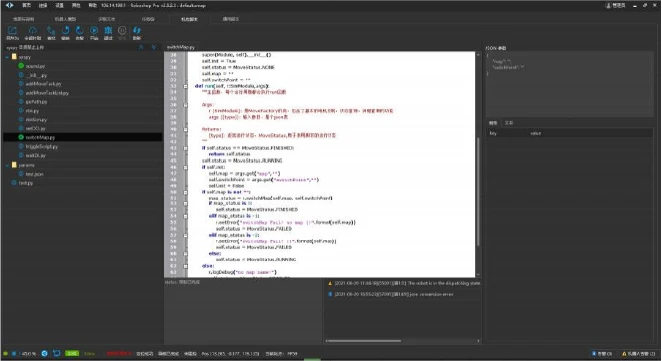

Robot Alert Handling

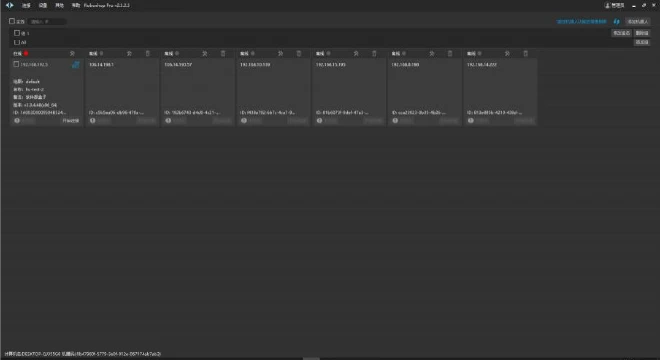

In the Roboshop Pro tool, real – time visibility of running errors and wizard – like solution buttons help users to find out the reasons of robot exceptions.

Roboshop

The deployment of AMRs can be quickly achieved

one-stop implementation tool

Instruction

Home Page

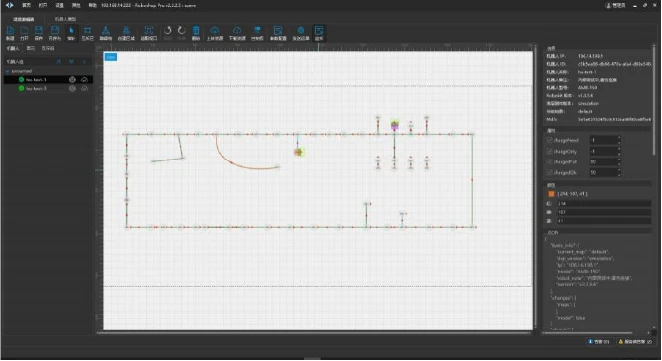

Manages and configures all intelligent equipment in the LAN uniformly, including robots, intelligent equipment and various automation devices.

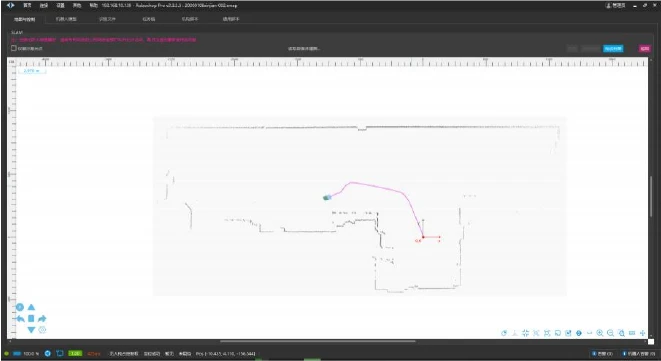

SLAM

Simultaneous localization and mapping enables 2D or 3D maps to build accurately and efficiently.

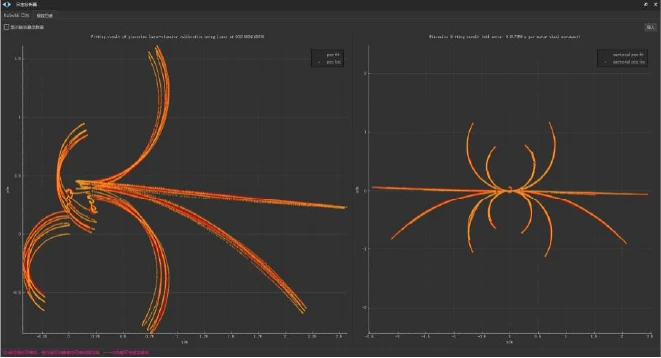

Robot Calibration

Automatic calibration process eliminates mechanical and assembly errors to ensure the consistency of multiple robots.

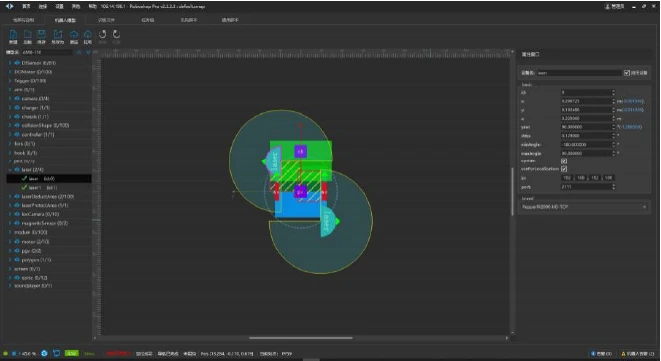

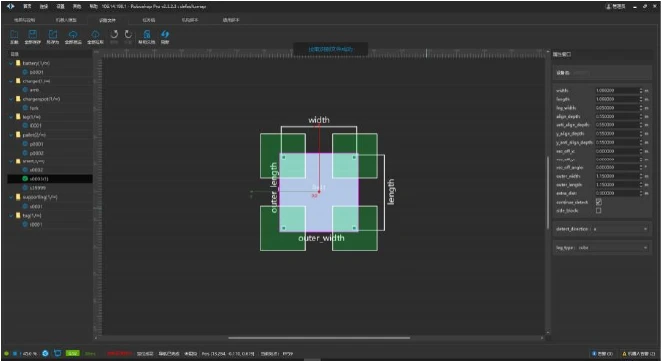

Robot Model Editing

Visual robot model editing covers size, motion model, drive model, lidar model, motor position, sensor position, peripheral mechanism and more, thus robot making is as simple as building blocks.

Map Editing

With easy-to -use map editing tools and high detail control, it can be smoothly edit even for large maps and what you see is what you get.

Robot Controlling

The robot is controlled in real time; The manual and automatic modes are freely switched, and the API commands are fully covered.

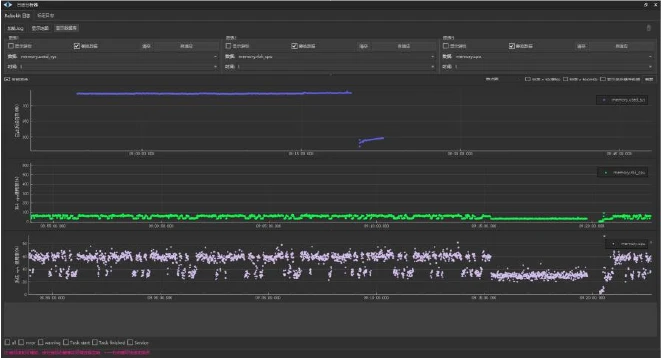

Log Analysis

Integrated log analysis tool analyzes robot running logs

automatically, easy to check errors.

Script Editing

With Python script programming, it’s beyond doubt tocontrol however complex the peripheral mechanism and logic are.

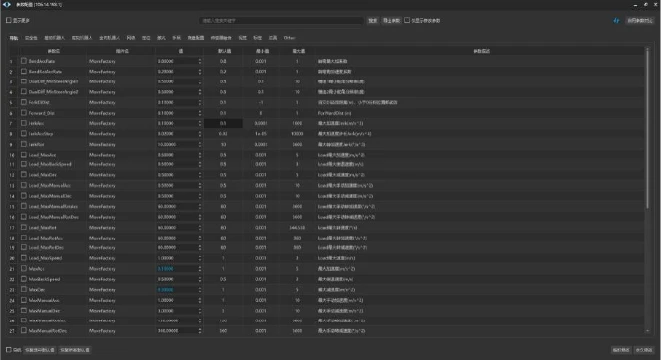

Parameter Configuration

Rich configurable parameters to grasp details at your fingertips. Running Status Detailed status monitoring to get robot data at a glance.

Running Status

Detailed status monitoring to get robot data at a glance.

Recognition Object Model Editing

Visual recognition object model editing allows all kinds of shelves, racks, pallets and cages to recognize online.

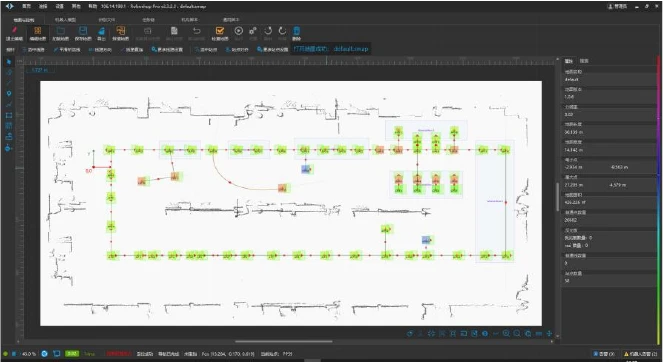

Dispatching Scenario Editing

Integrated with RDS Core dispatching system, scenario editing adds such scenes as multi-type and multi-floor robot maps, charging piles, mutually exclusive areas, lifts, traffic lights, control cabinets, and automation devices for unified dispatching management.

If you have any qustions, feel free to reach out and we’ll respond as soon as possible.