Exploring AMR

Together

Cost Savings and Efficiency

With autonomous navigation, automated material handling and transportation, the AMR replaces manual operations, integrates precisely into various production processes and adapts to different working environments.

Latent AMR

Latent Jacking robots are designed to move in low-clearance spaces. They Jack shelves or pallets from above using an elevated platform and navigate in confined spaces to retrieve or store goods. This type of robot is typically used to increase storage density in warehouses, especially in situations that require high-density storage and efficient material handling.

Smart Forklift

Smart forklift AMRs combine traditional forklift functions with autonomous navigation, performing material handling and stacking tasks in warehouses. These robots play a crucial role in industrial processes that involve logistics and warehousing, especially where heavy loads and high-shelf storage are required.

Composite AMR

Composite AMRs combine an AMR chassis with mechanical arms or other upper structures to meet non-standard, adjustable functionality. Common configurations include robotic arms that can perform complex tasks such as welding, parts assembly, or quality inspection at different stations, or custom roller mechanisms for material handling at the production line. This type of AMR usually requires custom development based on specific needs.

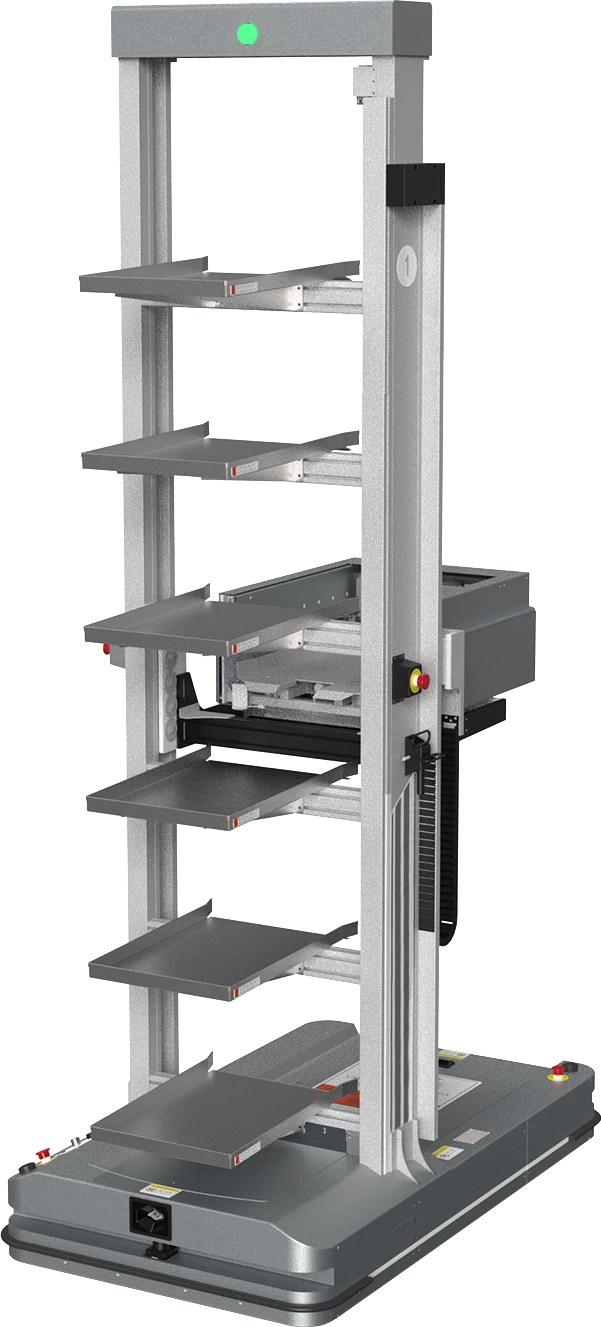

Multi-layer Carton Transfer AMR

Multi-layer Carton Transfer Robots are autonomous mobile robots specifically designed for retrieving and handling material boxes. By optimizing space utilization, they can achieve high storage density and deep deployment. Additionally, these AMRs can adapt flexibly to business changes, enabling frequent, fast, and accurate retrieval of goods. They are widely applied in storage, distribution, manufacturing, and service industries.

Automatic Cleaning Robot

AIVISION Autonomous Cleaning Robot is a cleaning robot specifically designed for industrial environments. It features automatic dust pushing, mopping, self-charging, automatic clean water replenishment, and wastewater discharge. It can also collaborate with other AMR (Autonomous Mobile Robot) systems for seamless operations.

If you have any qustions, feel free to reach out and we’ll respond as soon as possible.